By Bertrand Chovet, Managing Director & Partner at Interbrand, Paris

These thoughts were initially presented at Green Unplugged: Communicating Sustainability in London, June 7th.

As brands continue to recognize the positive impact that sustainability has on long-term brand value, they’ve been taking action to reduce waste.

In the last 20 years, there’s been a significant reduction in the use of plastic used in packaging. For example, the packaging used for a 1.5-liter mineral water has been reduced by 42 percent. Additionally, a container of 125 gram yogurt has been reduced by 40 percent. But while this is great news, businesses could go even further. As an October 2009 ADEME survey shows, 73 kg (13 percent) of an average 530 kg per capita loaded each year on our shopping cart is packaging waste. Businesses may have made strides, but they shouldn’t stop focusing on the waste issue.

So what are the next steps that brands must take to reevaluate their packaging strategy? Some brands like Danone, Newton Running, and Snyder’s are proving that there is no one sizefits all solution. The best strategy is one that is right for your brand.

Danone: Short-term risks,long-term benefits

Danone decided to get rid of its yogurt cluster packaging as part of an initiative to reduce its carbon footprint by 30 percent by 2012. The move was more difficult than initially expected.It required over three years of reengineering.

The problem was twofold: Not only would eliminating the cluster pack put key brands like Activia and Taillefine at risk as the packaging protects the product during its transport, but it would impact visibility on the shelf. Consumer research, in fact, identified a potential 20 percent drop in sales if Danone got rid of the packaging.

And yet, for Danone, the positives outweighed the negatives. While the short-term impact would be negative, a reduction in packaging would secure its long-term brand value and ultimately save the company EU 2.5 million (two cents per pack) a year. Although the reengineering took three years of planning and required true commitment and focus, Danone can now safely say that it is on course to reducing its carbon footprint by 30 percent.

Finding a partner Snyder’s of Hanover wanted to reduce the packaging used for its organic pretzels. Rather than create something on its own, Snyder’s found support in Clear Lam Packaging, which specializes in creating packaging from renewable raw materials.

THE 5R’s approach

One of the simplest approaches to reducing packaging waste is the 5Rs.

RETHINK

Analyze user behaviors and expectations (how they think, what they need and want) to deliver options about the cycle of the product and packaging. Use this research as a path for all engineers, marketers, and designers.

RE-ENGINEER

Look at packaging manufacturing, logistics, retail, and user constraints, involving both engineering and marketing disciplines before briefing designers.

REMOVE

Optimize packaging layers to fulfill manufacturing, logistics,retail and user expectations without losing the key packaging functions (which often have multiple uses).

REDUCE

Act to reduce packaging material without affecting the product performance during its production, transport, distribution and use phases.

RECYCLE

Consider the life cycle of the product packaging to improve how used material re-enters the process at the end of the cycle – especially from a user point of view.

Clear Lam replaced Snyder’s conventional petroleum-based plastics with renewable raw materials that are 90 percent plant-based. The renewable raw materials are produced with as little as half the energy of the petroleum-based packaging.

They also generate 52 percent fewer greenhouse gas emissions in the manufacturing process.

Additionally, the bag acts and feels like a conventional bag – something that was a major engineering challenge. Snyder’s move represents a major milestone. It is a packaging solution that is positively impacting manufacturing and the environment.

Newton Running: Innovating on its own

Newton Running, which is named for Sir Isaac Newton and the science behind energy conservation, has strived to produce shoes with minimal impact packaging. In Spring 2009, it launched a new rectangular shoebox to supplement this effort.

The new shoebox, which minimizes the energy the brand requires for production and shipment, is produced from 100 percent post-consumer waste and uses soy-based inks and aqueous (water-based) coating. The new packaging is not only easy to store and ship, it is also lightweight and easy to break down and recycle.

Additionally, as the box is produced close to the footwear factory, the business has minimized its shipping carbon footprint. Rather than tissue paper, it also uses recycled cardboard inserts (scraps from the box) to protect the shape of

the shoes.

The 5Rs in action, Bobble

Bobble Bottles

A great example of a brand that utilized the 5R approach effectively is the Move Collective. Under its bobble water brand, the company, with the help of designer Karim Rashid, came up with a solution to reduce bottled water waste.

Although the bottle water market is lucrative (US $17 billion per year in America), it is highly wasteful. It produces 38 billion units and uses approximately 1.5 million barrels of oil to deliver plastic bottles to each of us. Meanwhile, the plastic bottles contain the same beverage that most Americans can get from their kitchen sink. The Move Collective felt there could be abetter way.

First, the Move Collective rethought the bottled water market – how could it improve the industry by using water where it is, limiting transport, and logistics? Once this was determined, it re-engineered by observing the needs and behaviors of customers. This resulted in the creation of hybridized water purifiers.

Then it removed. A minimalistic, structural design was created that conveyed what the brand is all about: simplicity. Reduction was next. The Move Collective ensured that its Bobble water could be refilled at least 300 times before changing the filter.

Finally, Bobble, which is made from recycled PET, free of BPA, Phthalates and PVC, is also 100 percent recyclable.

All this, and Bobble also retails for under US $10.

More packaging solutions

As Snyder’s partnership with Clear Lam shows, brands have more opportunities than ever to partner with companies specializing in sustainable packaging.

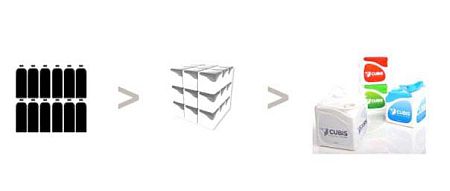

One particularly appealing packaging alternative that has been garnering awards since mid-2009 is Cubis, a patented beverage container. Cubis is targeted at the drinks industry and brings a number of benefits to producers, distributors and consumers.

Cubis Packaging

Cubis does a number of things effectively:

1. It cuts costs as well as carbon emissions by utilizing space during distribution and storage more efficiently.

2. It has a sealed off drinking spout which is ergonomically designed to ease drinking and demonstrates a higher level of protection against contamination.

3. Easier bottle stacking increases shelf value and simplifies logistic and handling.

4. An eye-catching structural design facilitates the introduction of new beverage products to the market.

While we’ve yet to see a brand use Cubis on the market, in the next year, expect to see some brands adopt the packaging.

Four tips to success

As the brands above demonstrate, there are a number of routes to take to reduce packaging waste. However, although solutions may vary from brand to to brand, the following points will be helpful to all brands when reevaluating their packaging:

1. Source the impossible

Choosing ignored or rejected materials will provide you with a competitive advantage.

2. Hybridization & mix

The power of association is often a key element of success. Mixing needs or expectations is key to attaining sustainability.

3. Start small

By experimenting on a smaller level, you can take advantage of a quicker return on experience, before beginning to implement on a larger scale.

4. Anti-Ecosystem

Changing the rules within you market can help you evolve.

Conclusion

Famous chemist Antoine Lavoisier stated «nothing is lost, nothing is created, all is transformed.» In regards to the sustainable packaging issue, this seems to be a good motto. It is tough to reinvent functions or behaviors; instead, new sustainable packaging solutions are brought to life by challenging those that already exist.

About the author

Bertrand Chovet seeks to build brand distinctiveness and consumer loyalty in every single client engagement. As Managing Director of Interbrand Paris, his commitment to high performance has resulted in many award-winning retail and package design programs.