Before the pandemic, the most global problem for environmentalists was plastic waste, but now a new era is filled with medical masks. Based on the data of experts, about 1.56 billion used facemasks in 2020 got into the waters of the World Ocean. This is more than the population of jellyfish worldwide.

Unfortunately, the world society still does not cease to be indifferent to the environment. People throw away facemasks, rains wash them into rivers, which then carry them out to the seas and oceans. According to the organization OceansAsia, there are 1.56 billion masks, which are about 3 percent of all face masks produced in 2020 (129 billion units).

Today, remedies are found even on the most uninhabited beaches, where there are practically no people. According to representatives of OceansAsia, if at the very beginning the volunteers collected about 70 facemasks a day, now we are talking about 150 per hour. The debris has already begun to threaten the lives of animals. Not so long ago, a penguin was found in Brazil, who died from a swallowed fascemask. This was the world’s first death from «pandemic debris».

Mask makers are chasing profit, not conscious consumption, which is gaining momentum. Companies made $ 137 billion in non-degradable masks. But there are other brands — which put the interests of nature over the interests of earning.

Marianne de Groot, a designer from the Dutch studio Pons Ontwerp, has created biodegradable rice paper-based facemasks called Marie Bee Bloom.

The material is made from a mixture of rice, water and natural starch. Headbands made from regular yarn can be adjusted in length. The parts of the facemask are glued to each other using potato starch.

The innovation of the product is that their facemasks can be buried in the ground and flowers will grow out of it: there are seeds between the layers of paper. With proper use and care, you can admire the bouquet in a couple of weeks.

Garrett Benish and Elizabeth Bridges of Sum Studios decided to develop an antimicrobial cellulose face mask that anyone could grow in their own kitchen.

The so-called xylin facemask is made from bacterial cellulose, a byproduct of a common bacteria called acetobacter xylinum. This bacterium belongs to vinegar, living and developing in wine. Garrett and Elizabeth say you can actually grow bacteria like this with a few simple ingredients in your own home. All you need is water, tea, sugar, and a small bacterial sample of acetobacter xylinum, which can be found in kombucha.

Bacterial cellulose is created by acetobacter xylinum bacteria on the surface of the liquid in which it lives. As these bacteria multiply, they bind the cellulose fibers into a single membrane, which can later be compressed and dried for use like any other tissue. While cellulose is outwardly transparent, microscopic images show a dense web of cellulose fibers that make up an amazing dense material that decomposes in a fairly short time, soaking it or burying it in the ground like fertilizer.

Designer Alice Potts has combined food waste and flowers from London parks to create a series of bioplastic face screens as part of the NGV Triennial at the National Gallery of Victoria in Melbourne.

Protection screens, dubbed Dance Biodegradable Personal Protective Equipment (DBPPE) Post Covid Facemasks, are biodegradable according to the designer.

For the triennial, the designer created 20 masks, each with a 3D printed top combined with a biodegradable bioplastic protection screen. The color and precise structure of each screen depends on the food it is made from and the colors it is painted with.

Alice Potts says that she collects food waste in local markets, in butchers’ shops and at home. «Most vegetables can be made into dyes, fruits act like natural sugar for flexibility in bioplastics, while proteins can be used to give strength to the plastic itself.»

Biodegradable facemasks are not only environmentally friendly, but also aimed at combating depression, which appears due to the lack of visible emotions in people.

Scientists of the Lausanne Polytechnic School suggested making completely transparent masks made of biodegradable material. The development was named HelloMasks. It took more than two years to create the material, the very idea of making such masks for doctors came up with scientists in 2015, but during the pandemic it became relevant again. Masks will begin to be released not earlier than the beginning of next year.

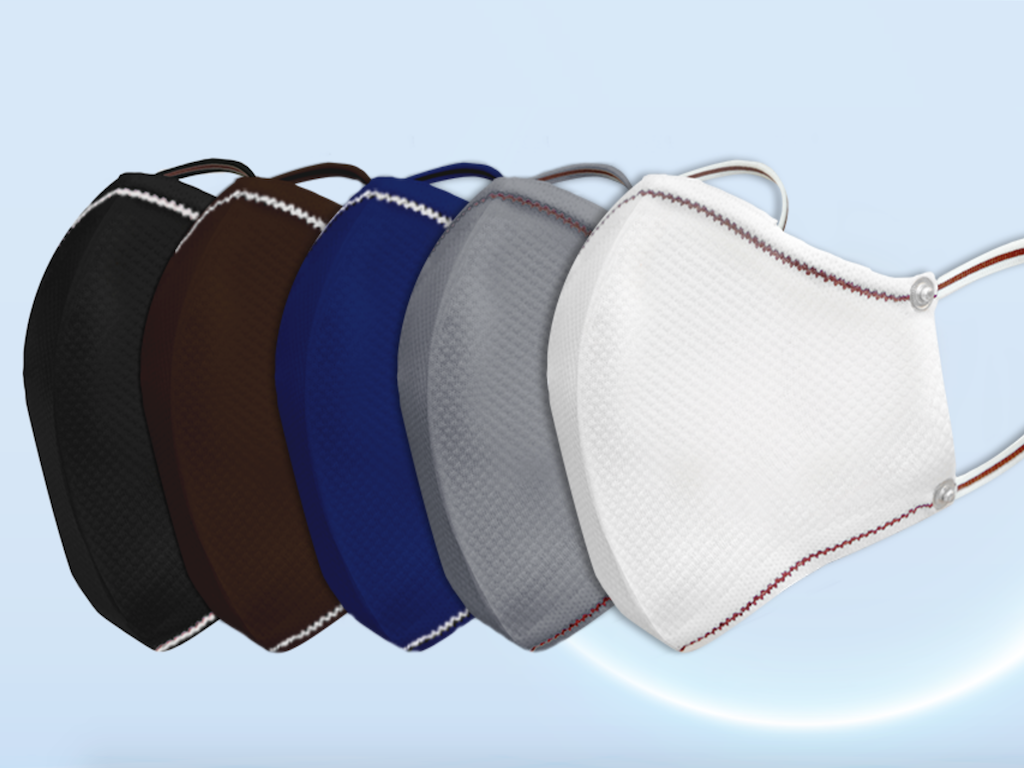

ShoeX, the Vietnamese footwear company that made coffee shoes, has just launched its new line of coffee facemasks. The AIRX mask is made from Vietnamese coffee beans and is reusable, biodegradable and antibacterial. The company hopes this will help protect people from the coronavirus without further burdening the planet.

ShoeX says it has a current capacity of 10,000 masks a day to meet global demand. This will not only lessen the waste crisis exacerbated by the use of disposable face masks.

According to the company, the coffee face masks are designed with 99.99% dual antibacterial technology — first layer is made of coffee thread, and the second is a biodegradable filter created using nanotechnology based on coffee and silver. It has been approved by the AATCC 100 certification, the textile industry standard for antimicrobial properties in the United States.

As we can see, the planet has a chance for a «clean» existence. Thanks to interested companies around the world and the accessible platform education of applied sciences, a trend is emerging: almost every manufacturing industry is taking a benchmark not only for green production, but also for an environmentally friendly biodegradable product.