Edible Expectations

In other categories, the market is ripe for such innovations. So the Marriott hotel chain began to implement a policy of banning the use of plastic in its British hotels from February 2018. To date, more than 60 hotels in the UK have already phased out plastic straws in the first place and are now offering straw alternatives to consumers. This includes Le Meridien Piccadilly, Grosvenor House & W. in Leicester Square.

The Hilton brand has also announced it will be phasing out plastic straws and water bottles. The initiative of the world leader in the hospitality industry came in May 2018, when the UK government actively started talking about a nationwide ban on the use of single-use plastic.

In July 2018, beverage giant William Grant & Sons released its annual market report, highlighting the rise of “active consumers” who are increasingly voting with their wallets for products and services that are in line with their ethical and political views.

Therefore, beverage and hospitality companies have had to rethink their approaches to sustainability in order to keep a new generation of environmentally conscious customers from walking past their door. Moreover, as marketing director of William Grant & Sons Matt Billinghurst noted: “Consumers want it quickly,” hinting unequivocally that brands have no time left to build up.

Manufacturers immediately redistributed their resources, focusing on the search for materials and technologies to cover the demand for biodegradable edible packaging. And it turned out that those materials that were previously viewed as garbage are now ideally suited for similar environmental initiatives in the packaging segment around the world — the USA, the EU, Eastern Europe, Southeast Asia.

For example, Evoware eco-packaging is made from seaweed. The Indonesian-based social company understands the urgency of excess waste like no one else. Therefore, she directed her research in R&D to the development of bioplastics.

Evoware products are made without preservatives, have a two-year shelf life, and are developed in collaboration with algae farmers. All products have a halal certificate, which confirms their absolute safety. The edible packaging line includes coffee and dry seasoning sachets, food packaging for bread, hamburgers, sandwiches and more.

Biodegradable Ecoware products are 100% waste-free — they dissolve completely in water and act as a natural fertilizer for plants. The manufacturer is happy to take on private label projects, thereby promoting an environmentally friendly approach to packaging.

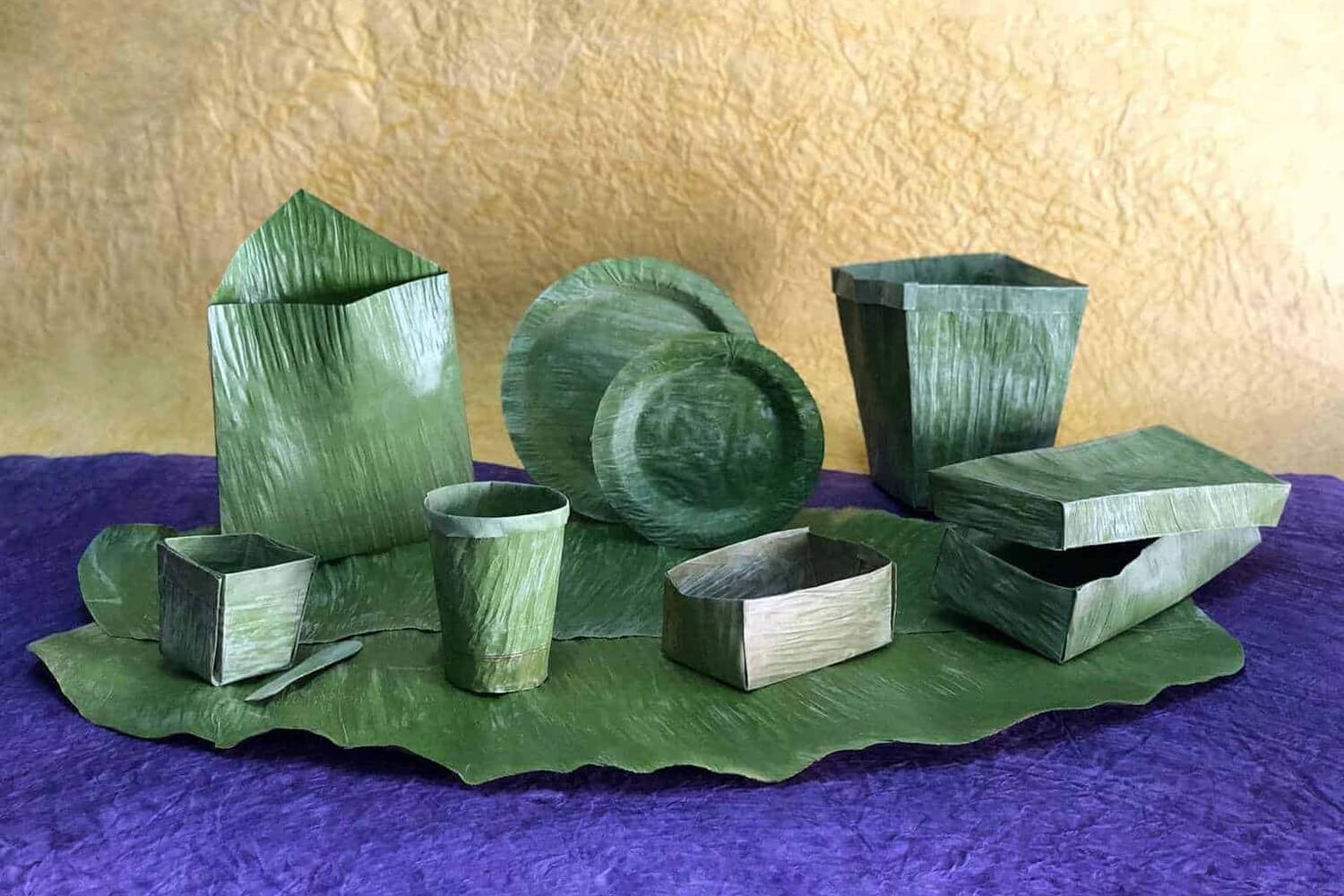

Indian startup Banana Leaf Preservation has come up with a sustainable solution to the global problem of disposable polymer items. Banana leaf canning technology can not only replace single-use plastic, but globally resists deforestation.

Banana Leaf Preservation Technology is an eco-friendly cage system that preserves banana leaves for up to a year without the use of any chemicals. In the natural world, leaves and most biomaterials decompose and are discarded as waste after a three-day storage period. Startup development improves the physical properties of plants, creating a viable and biodegradable alternative to paper and plastic.

The processed biomaterial is chemical free, cost effective, 100% biodegradable in nature within 28 days (plastic typically degrades in nature in about 730,000 days). This contributes to solving the global waste crisis and could help prevent the death of 20 million terrestrial and aquatic animals.

Due to the economic, innovative and environmental impact of its technology, Banana Leaf Preservation Technology has received more than 7 international awards and 2 national awards, including the prestigious International Environmental Award, International Green Technology Award and the Future Technology Award.

UK-based startup Pacific Camp’s single-use packaging solution is unique in its kind. An innovative company has developed a technology for the production of biodegradable eco-tableware from alfalfa.

More than 100 species of alfalfa are known in the world, but only 4 of them have an economic purpose (two are wild). A perennial herbaceous plant, known for its highly nutritious properties, has been used since ancient times as a fodder crop for livestock. Pacific Camp’s technologists have turned alfalfa into the basis for producing an alternative replacement for single-use plastic, elegantly solving an important environmental problem and, at the same time, providing their need for cheap renewable raw materials for a long time.

Pacific Camp products are currently being tested in the UK and Estonia, and once regulatory procedures are completed, the company plans to start commercializing its development with a major food tech partner, whose name has not been disclosed.

«Plastic Renaissance»

The most amazing thing that happened to the post-COVID packaging market is that plastic has a chance for a second life. Despite all the international controversy and universally accepted international programs to reduce polymer packaging, eco-enthusiasts were in for a big surprise. The spread of the coronavirus has fundamentally changed the situation in the packaging segment.

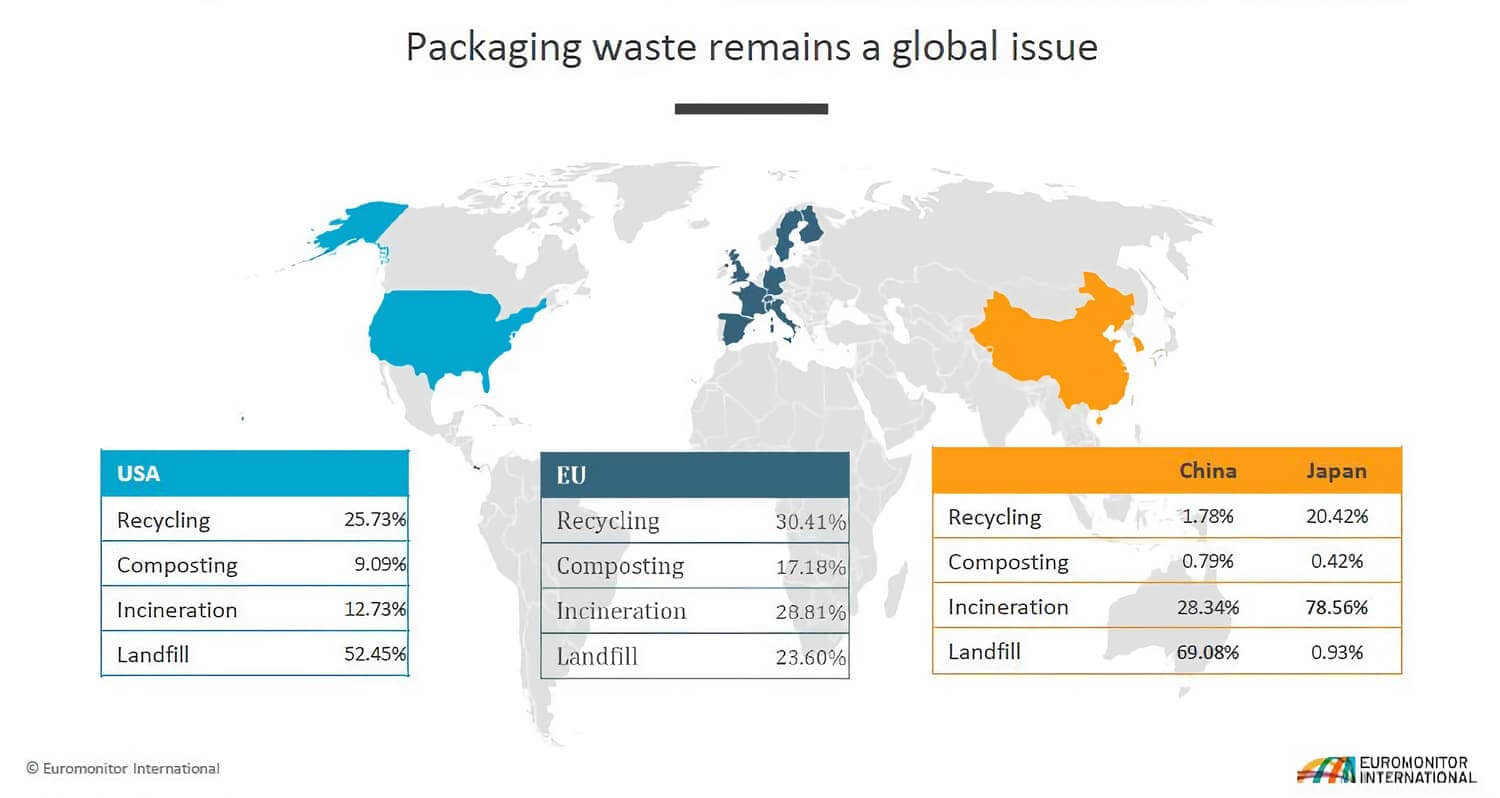

“Single-use plastic packaging has become a staple,” says Euromonitor International analyst Thea Fening. – The trend towards environmentally friendly packaging, which was gaining momentum in the world, has stalled, and major players have begun to change their attitude towards plastic. In terms of ecology, in terms of the amount of use of non-recyclable plastic packaging over the 2 years of the pandemic, we have taken a step back.”

Nomadic Dairy Yogurt & Oat Clusters has not gone plastic-free, but has announced that it has changed packaging to eliminate the need for unnecessary plastic by snapping cups instead of plastic wrap. The new crinkles are made from cardboard sleeves with foil lids and are fully recyclable. The new packaging also features a 100% compostable, renewable wood wooden spoon.

Nomadic Dairy’s revamped packaging for yogurt and oats saves 200 tons of plastic annually, delighting environmentally conscious consumers.

Another principle is not to recycle, but to reuse packaging. Currently, it is being actively implemented by cosmetic companies (for example, L’Oreal), as well as large retail chains in European countries and Japan.

The German cosmetics holding Beiersdorf is developing a filling machine for Nivea shower gels in reusable containers in one of the retail chains in Hamburg. This approach allows you not to throw away the packaging and return with your container for “topping up”, without polluting the environment. At the same time, the technology of smart engineering not only pours a new portion of the cosmetic product, but also pre-cleans the bottle itself.

However, it should be noted that after a certain number of cycles, a fairly decent amount of such packaging eventually turns into solid waste. And where there is no infrastructure for receiving used containers, it is not yet recycled, but is still taken to landfills.

Catering Issue

Catering advocated the return of single-use plastic. In early March 2020, Starbucks, a well-known fan of eco-trends, announced the use of exclusively disposable drinkware in its establishments in the US and Canada. Today you will not be able to pour coffee into your mug in all the network establishments, as it was before. The company believes that this measure should prevent the transmission of the virus between visitors and employees of coffee shops. Dunkin’ Donuts did the same, opening a «plastic Pandora» box.

Today, the US expert community is publicly calling on lawmakers in New York, California and other states to urgently lift bans and regulations on single-use plastic utensils and shopping bags.

According to experts, the consumer properties of single-use plastic are one of the key, including hygienic, reasons why these packaging solutions have become widespread in the world. Scientists from the University of Arizona and Loma Linda University have indicated that reusable bags contain bacteria in 99% of cases and can pose a health risk to consumers. Coliform bacteria were found in 51% of reusable bags — from 3 to 3330 such bacteria were found in each bag.

An open letter from 13 scientists from leading American research centers, published March 17, 2020 in The New England Journal of Medicine, indicates that viruses and bacteria can persist in reusable bags for up to nine days.

Back in 2012, in a special study, scientists analyzed the impact of a ban on single-use plastic shopping bags in San Francisco and reported a 25% increase in cases due to the spread of bacteria in the city compared to other counties that did not have a ban.

Despite the paradigm shift, for a growing number of people, the “sustainability” of packaging influences the purchase decision. While the pandemic has taken a toll on consumer sentiment, 17% of shoppers in the US and about 18% in the EU are willing to overpay for sustainable packaging.

Whatever scenarios are predicted now, we can safely ostracize the option in which the environmental properties of packaging would suddenly become secondary. This will not happen in the short or medium term, let alone a longer planning horizon.

And since today we are talking about innovations in the market, the future belongs to eco-products. Today, biodegradable plant materials for alternative packaging are a steady trend that even such surprises as a pandemic cannot shake. Startups like Pacific Camp, which produce disposable eco-tableware basically from weeds, have huge prospects.