Convenience in Canning: The Mediterranean Fish Market

By Steve Thomas, Marketing Manager, CROWN Food Europe

Every year, around 12 billion kg of fish is consumed in the EU. That equals 24 kg for every EU citizen, which is well over the world average of 13 kg per person. What’s more, the demand for fish in Europe is growing. With busier lifestyles, consumers are becoming more conscious of the need to eat a nutritious and balanced diet in order to maintain good health. For them, fish is a great way to consume lean protein and also boost the nutrients and vitamins in their diets.

The Mediterranean diet, with its reliance on olive oil and abundance of fresh fruit and vegetables, has long been renowned as healthy. Consumers in this region also well recognise the health benefits of fish, which has driven significant growth for the canned fish sector over the past five years. One of the key nutritional benefits of products such as salmon and mackerel is Omega 3, a fatty acid proven to reduce risks of heart disease, strokes and cancer. Fish producers and manufacturers have become aware of consumers’ desire for healthier lifestyles and the demand that this in turn has created for new products that contain nutrients such as Omega 3.

This growth has also created new opportunities for the metal packaging industry to innovate and design solutions that offer consumers more choice while helping manufacturers differentiate their brands in an increasingly competitive market. Even in today’s difficult economic climate, metal cans continue to offer the most cost-effective way to package shelf stable foods. By offering a packaging format that provides versatility, sustainability and convenience to consumers, they are able to better enhance the appeal of their products and target demographic segments in which demand for these three characteristics is rapidly growing.

Let’s take a look at how each of these characteristics become critical differentiators.

Versatile and Sustainable

The inherent strength of metal cans offers robust protection for the product throughout the supply chain, from manufacturer to retailer, delivering high quality products at low cost. Can manufacturers, like CROWN Food Europe, continually monitor can quality during the manufacturing process to assure that standards and requirements for universal can specifications are met in the markets they supply.

The combination of a wide choice of fish can sizes together with long shelf life means the consumer can use these products at home straight from the cupboard, conveniently and very quickly without the need to store them in a fridge or freezer. This not only saves on energy costs but also helps reduce food waste, an important objective for the cost-conscious consumers.

Furthermore, the unique properties of metal cans makes them 100% recyclable – they can be recycled again and again and again without loss of material quality — meaning that in a new life they can come back as a new can or other metal goods like cars or fridges. The result is that metal is the most recycled material in the world compared to all other shelf stable packaging formats, a significant fact for resource savings.

The can also offers a large surface area for brand messages and can be decorated with a wide range of eye-catching finishes or formed in unique shapes. These techniques help cans stand out on retail shelves and add consumer appeal. The options available from Crown include a wide range of bowl-shaped containers particularly suited for ready-to-eat foods. This format allows on-the-go consumers to serve the product directly from the bowl.

Creating Consumer Convenience

Canned fish products offer today’s busy consumer all the nutritional benefits that fish brings but in a format that is economic to store, easy to prepare and quick to consume.

Openability is key for all packaging formats and metal cans are no exception. Brand owners have several options when it comes to closure types on food cans including both rigid and peelable easy-open ends.

Crown’s recently launched Easylift™ patented technology, an evolution on its flagship Eole® easy-open end, offers greater consumer convenience by providing a larger gap between the can lid and tab, allowing easier finger access to open the can.

Crown has also invested in new lines in Spain for its PeelSeamTM peelable ends to manufacture round lids, as well as various other options such as club and oval to address the growing needs in this market. The PeelSeam™ peelable lid offers an alternative easy and safe way to open fish cans, as well as a more convenient way to consume fish, especially for on-the-go consumers who need food options to meet their busy lifestyles.

PeelSeam™ peelable lids can also be printed with high quality graphics which, in combination with similar graphics on a bowl-shaped container, produce an extremely appealing premium looking package. This is one of the reasons why Capitaine Cook chose this format to re-launch its “Odyssee” branded range of fish-based ready meals.

Crown also worked with Calvo, a leading manufacturer of canned fish products in Spain, to develop a decorated 65mm diameter bowl for its new fish pâté. The PeelSeam™ peelable lid was incorporated into the overall design together with a plastic overcap enabling the consumer to re-close the product for a later re-use.

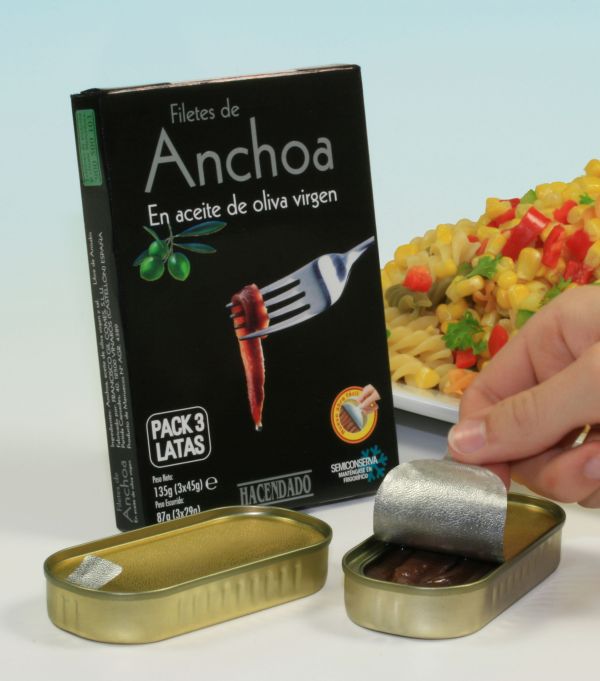

Recently, Crown also supported Spanish anchovy canner Gil Comes with its conversion to PeelSeamTM lids on their 80g rectangular cans distributed by Mercadona, the leading Spanish retailer, who is committed to this modern form of closure in the shelf stable fish product market.

Expansion in the Mediterranean

Canned fish already has a 26% share in the estimated $26.4 billion European canned food industry, according to Datamonitor, and this is set to grow as demand increases.

It goes without saying that the Mediterranean region represents an important market for the canned foods industry in Europe. Spain holds the largest volume for the canned fish market and it has been identified as the largest growing sector within the industry. According to a Business Insights report, between 2002 and 2007 retail volumes for canned fish rose from 166,800 tonnes to 204,300 tonnes throughout the Mediterranean. Between 2003 and 2007, the number of new fish products introduced to the Mediterranean market increased by 16%. As metal packaging is such a convenient solution to meet this rising demand for fish products, a number of packaging companies have increased their operations in the region.

Crown already has a strong presence in the market with large manufacturing plants for fish cans located in key fish filling locations such as Galicia in Northern Spain and Casablanca, Morocco. Indeed, in 2008 Crown announced that it would be opening a second plant in Morocco, based in Agadir, expanding Crown’s ability to supply a full range of cans to serve the growing European market.

Conclusion

Over the next few years the demand for fish products is forecast to grow. Metal packaging is well positioned to help brand owners meet this increasing demand. Metal cans meet the needs of the whole distribution chain, from manufacturers to retailers and most importantly to the consumers at the end of the line.

Whether the issue is convenience, sustainability, logistics or brand awareness, new metal packaging technologies offer innovative solutions that will allow fish manufacturing companies to continue meeting evolving market demands for many years to come.

About Crown Holdings, Inc.

Crown Holdings, Inc., through its subsidiaries, is a leading supplier of packaging products to consumer marketing companies around the world. World headquarters are located in Philadelphia, Pennsylvania. For more information, visit www.crowncork.com.