Millions of tons of food move daily between B2B suppliers and retailers. Supply chain failure causes stores to collapse. How businesses are responding to modern logistics challenges and what transportation solutions can affect food delivery. Understanding the huge variety of trends in modern logistics.

Crucial Relations

Did you know that trucks are responsible for transporting 70% of the goods in the US?

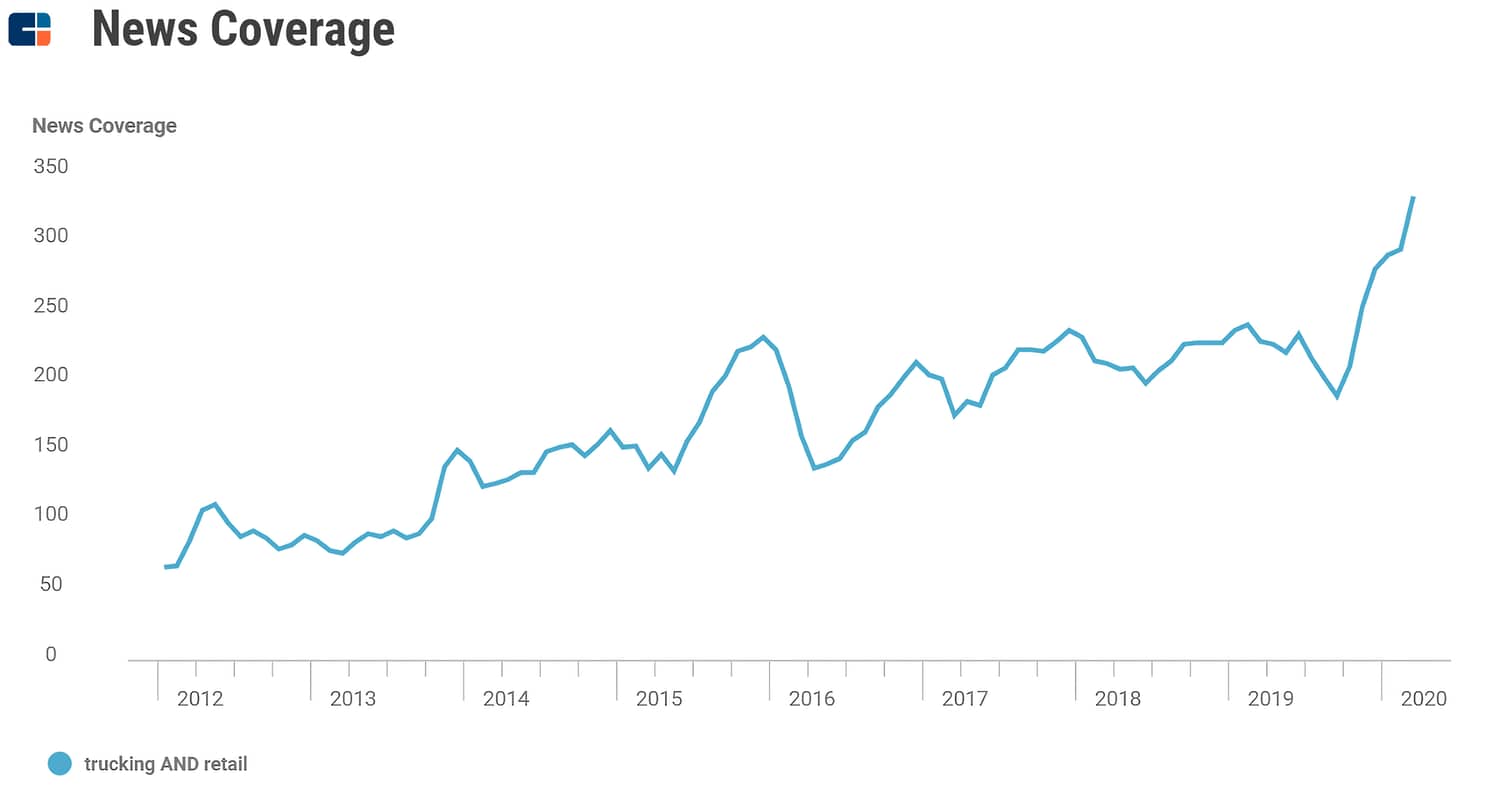

Retailers today are very dependent on the shipping industry to reduce delivery times, stock outs and increase the overall speed of shipping products to customers. Any external factor draws increased attention to the joint problems existing in the market. Consider how many major cataclysms we have experienced over the past three years, from the pandemic and lockdown to supply chain disruption and price increases in the post-pandemic era. And all this wave of black swans only exacerbates the already difficult situation with the logistics chain.

For example, consumer demand for fast home delivery during the pandemic has prompted retailers (e.g. Target, Walmart) to enforce rigorous OTIF programs (on time and in full) by imposing hefty fines on suppliers for incomplete or delayed shipments, creating even more tension. between truckers, suppliers and retailers.

Add to this an aging workforce and a lack of youth appeal to the driver profession, which has resulted in a serious shortage of drivers, further complicating logistics in the FMCG industry. The National Retail Federation estimates that the US must add at least 1.1 million truck drivers over the next decade.

Equally damaging to the trucking industry is the slow adoption of technology. First of all, in the lack of transparency in the relationship of all parties. The traditional approach to the means of transporting goods and food carries additional risks, and the industry, having survived one attack, immediately faces another serious obstacle. Rising energy prices and a general economic downturn are currently one of the most serious risks for the survival of players at various parts of the supply chain.

There is no immediate solution to the problems. And this is hardly possible. The more valuable is the experience of startups in the field of logistics and cargo transportation, trying to respond to global challenges.

Ecosystem Crisis

The current collapse of transportation, when tons of food cargoes are available, but in the ports of the largest countries of the world, thousands of ships clogged with them to capacity have accumulated, has also led to a food crisis, from which not only developing countries are already suffering.

In the face of logistical chaos, the number of hungry will grow even faster. According to the largest container shipping operator, the Danish firm Maersk, it is generally unknown when the supply crisis will be resolved.

For every optimistic forecast, there are 2-3 or more pessimistic ones, who claim that the logistical crisis, and hence the problems in the food sector, will last the whole next year. Among them are not only couch experts, but also influential people, for example, the chairman of the US Federal Reserve.

Therefore, startups in the logistics segment are not deprived of attention today. Both consumers and investors turned their attention to them — especially. Some with hope, others with passion to break the next jackpot. To be clear, new entrepreneurial initiatives are expected to provide solutions that can not only meet the current challenges of the freight industry, but also expand opportunities for the entire broader logistics ecosystem.

Not everyone will survive, but those who cope with long-standing challenges will easily turn into new giants — the flow of money from investors has long turned into a mighty river. We analyze how the transformation of the supply chain and logistics is seen in the future. Innovation today is taking place in a wide range of areas, from freight transport to tracking the food supply chain to autonomous delivery of the last mile. It is on the delivery of food that we try not to focus, it just happens.

A new way of inventory management

Proper planning of enterprise resources ensures the stable operation of its trading systems. However, this approach to sustainability comes at a cost. For example, holding a $1 unit of product as inventory for a year costs between 15 cents and 35 cents. The annual cost of inventory maintenance is 20 to 30% of their purchase price.

For example, if a company’s average inventory is $100 million, the company spends approximately $25 million a year to maintain it. Therefore, as soon as problems arise at this stage, it is almost immediately reflected either by empty shelves or by an increase in the prices of products in the shelf space.

Startups such as Nextail Labs are struggling with this. This developer’s software allows you to optimize inventory allocation for retail and FMCG businesses. Or San Francisco-based ClearMetal, which has created a buzz with its AI-powered supply chain analytics platform tailored to the needs of logistics and transportation process management.

The startup offered its customers to track the delivery of their orders around the world, helping to predict which carriers will provide the most reliable service and assess the risks of delays. Not everyone has reached the finish line, but Infor startup solutions for integrated control and distribution of resources, procurement, production and logistics are one of the leaders in the segment.

Food supply chain

Increasing the efficiency of the global food supply chain is also a top priority for the industry. Many companies are working on these tasks. Startup Apeel Sciences, for example, uses plant extracts to create invisible, tasteless coatings that extend the shelf life of fresh produce.

The company’s technology can help grocers reduce waste while improving the appearance and nutritional value of fruits and vegetables. Costco began selling Apeel coated avocados back in June 2018.

Brazil-based digital broker CargoX is helping shippers and carriers reduce delivery times, which is important for perishable food products, in an attempt to mitigate the impact of supply chain disruptions. For retailers, the ability to track their shipments in real time has proven to be extremely popular. This helps them improve key scheduling metrics by avoiding overstocking and reducing defectives and regrading.

Fleet Management

For cargo transportation, the reservation of transport remains important. Platforms like California-based Cargomatic are doing this effectively, making a big difference in simplifying the truck booking process.

To date, Cargomatic has built perhaps the most reliable cargo platform in the industry. With the integration of terminals, SSL, TMS, railway lines, billing systems and corporate ERP systems, Cargomatic approaches fit perfectly into supply chains of any size.

The startup connects shippers and carriers online in real time, and has also become one of the pioneers of contactless logistics, no matter where customers import or export goods. Cargomatic’s capabilities extend to 20 of the largest ports in the continental United States, meeting the unique needs of shippers.

TrueNorth Texans are also developing their digital platform for independent truck drivers. With its help, truckers-individuals are able to compete with large fleets. Partners are provided with software for cargo management, routes, shipper relationships, invoicing and more.

New warehousing system

CommonSense uses a hybrid execution approach. The robots within the walls of it’s site, controlled by their own software, break down orders into tasks and delegate these tasks to stages autonomously — deliver goods in containers waiting to be shipped to teams of employees who pack individual orders. Other robots move packaged orders to shipping, where they are loaded onto a scooter or van.

An Israeli company is reinventing ways to sell and deliver goods in cities. To grow effectively in retail today, you need to be closer to your end customers. In megacities with dense buildings, this is sometimes difficult to do. Finding a solution is costly, but does not always lead to cost-optimal solutions. CommonSense didn’t just invite retailers to place online orders in close proximity to shoppers. The company plans to increase the profits of its partners through the use of its own automatic solutions.

Last Mile Delivery Services

Once popular companies offering last mile delivery services to retailers through autonomous fleets of drivers and deliveries, such as

Postmates, an urban logistics and delivery platform that allows any customer to deliver any product within the city in less than an hour (in July 2020, the startup acquired Uber), is no longer the last word in innovation.

In our article on retail trends, we talked about promising companies are using robotics to close the last mile between the store and the customer. The review included Nuro autonomous mini-cars, which are already delivering goods to customers from Kroger and Walmart stores.

On the roads today you can see other successful examples in action. For example, Udelv’s autonomous electric delivery service vehicles add flexibility to delivery windows and reduce the city’s CO2 emissions. If you are their client, you can significantly reduce overhead costs.

The last love of investors is last mile drones. Startups are making full use of drones in the form of autonomous vehicles to improve the efficiency of door-to-door delivery. The experience of players like Zipline (the company produces drones, delivering vital medical supplies to clinics with their help) is being adopted and transformed in the retail and HoReCa sector for food delivery.

Today, not only local companies are experimenting with drone delivery. U.S. retail giant Walmart has partnered with developer DroneUp to launch express drone grocery delivery in six US states. The service is deployed in Arizona, Arkansas, Florida, Texas, Utah and Virginia.

DroneUp drones deliver food and essentials from Walmart supermarket chains to customers, reaching a potential audience of 4 million households. The company’s goal is to reach the delivery of 1 million parcels by air per year.

Walmart has begun testing delivery drones to deliver COVID-19 testing kits and groceries. The developer at this time improved the platform for managing the air fleet. Apparently, the results of the cooperation satisfied Walmart — at the moment it is one of the largest drone delivery services in the US in retail. Considering that Walmart is actively investing in 34 dark stores that are equipped with drone take-off areas, the retail leader has huge plans.

The company notes that the cooperation between Walmart and DroneUp will not be limited to food delivery. Going forward, the startup will offer local businesses and municipalities solutions to serve other industries, including insurance, emergency response and real estate tasks. For example, construction agencies will be able to track the progress of work at their sites using aerial photography from drones.

Actively invests in the Google industry. With the help of Wing drones, the company began delivering food and medicine in the US, Australia and Finland. Over the past two weeks, at least 1,000 deliveries have been made. To use this functionality, the buyer simply needs to install the Wing application.

The company notes that the cooperation between Walmart and DroneUp will not be limited to food delivery. Going forward, the startup will offer local businesses and municipalities solutions to serve other industries, including insurance, emergency response and real estate tasks. For example, construction agencies will be able to track the progress of work at their sites using aerial photography from drones.

Actively invests in the Google industry. With the help of Wing drones, the company began delivering food and medicine in the US, Australia and Finland. Over the past two weeks, at least 1,000 deliveries have been made. To use this functionality, the buyer simply needs to install the Wing application.

Total digitalization

While the startups in this review are showing clear progress in digitizing the supply chain, many in the logistics industry are still stuck in the analog age. The situation began to change for the better due to collaborations — the transfer of experience is quite capable of pulling the industry out of a deep crisis.

For example, digital freight forwarders Flexport are actively helping third-party logistics companies develop their own digital platforms. Among the company’s clients are such delivery monsters as DHL. And startups like Clear Labs and the aforementioned Apeel Sciences are helping retailers navigate food safety and sustainability.

Last year, meat giant Tyson, through its venture arm, invested in North Carolina startup FoodLogiQ, a leading SaaS provider of food safety tracking solutions. The FoodLogiQ Connect platform is today the most complete and effective information system for control and transparency of the entire supply chain.

In the end, companies in the industry that can even intuitively automate much of the logistics process while providing enough transparency to key stakeholders will be noticeably better off. And while the market has both a place and means for such an acceleration.